if I detect that the setpoint drifts out of the x%, I set my fine valve back to 50% and then re-adjust with my coarseĭepending on your physical phenomena, that may not be a good idea: imagine if you did this when your fine is at one of the extremes (say, below 10% and above 90%) - you're saying that you want to swing that to 50% - that might not be a good idea and could cause a big change, and maybe even an instability in your system. Has anyone done anything similar that could give me a few tips? Thanks all! I understand that I'll definitely need hysteresis so that my system doesn't switch back and forth at the x% point.

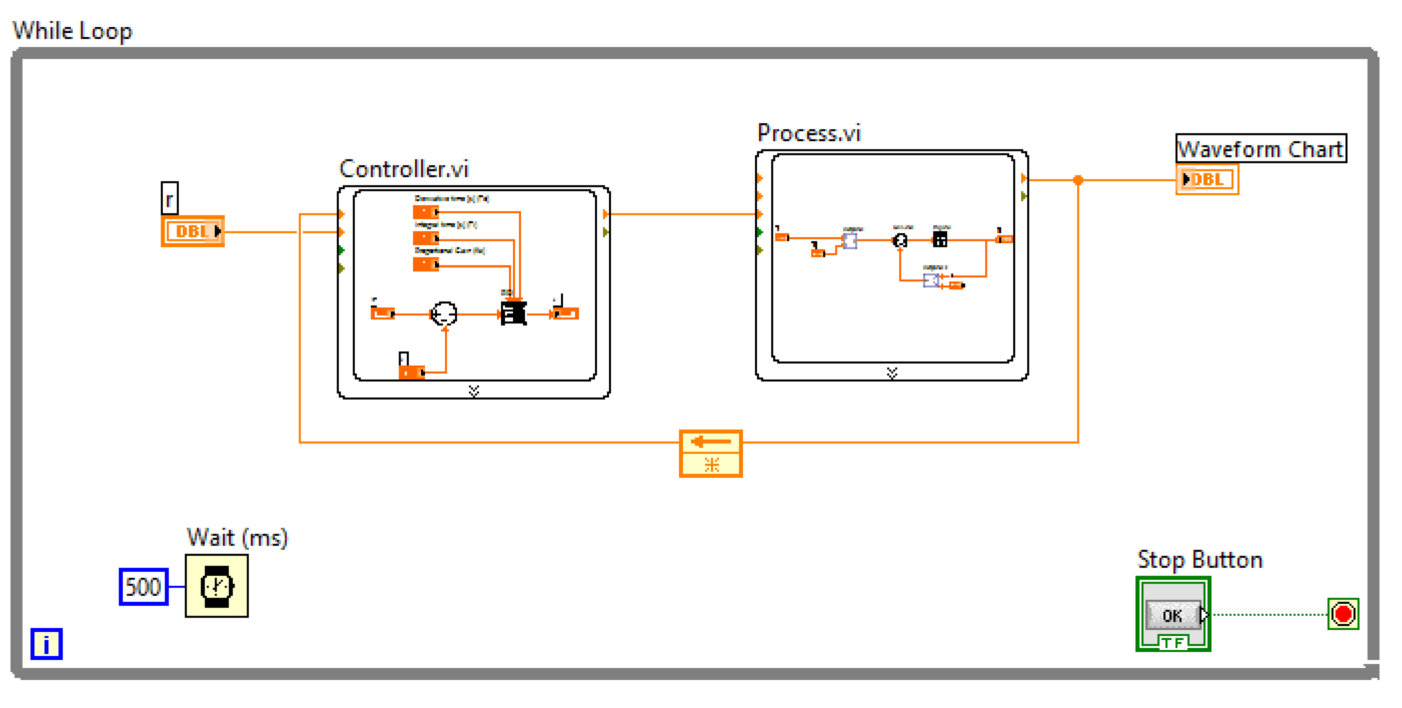

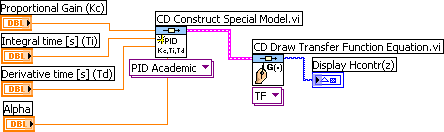

My worry is the switch points of this logic - How will the PID react? My hope is that since I'm constantly inputting and running both PID controls, my output won't jump when switching. However, if I detect that the setpoint drifts out of the x%, I set my fine valve back to 50% and then re-adjust with my coarse.īoth PID loops would be running constantly, however my logic would determine if I use the current values or maintain previous values to the system.

Once I get within the x% of the setpoint, I switch over to another PID loop, maintaining the current value of the coarse valve, and use the fine-tune valve to home in on my setpoint. If I am not, I set my fine valve to 50% open and adjust my coarse valve using PID until I'm within the x%. My thought is this: I monitor the feedback to see if I'm within x% (x to be determined) of my desired setpoint. My system must use these two valves in order to achieve a desired flow of the overall system. The input of the system is two proportional valves - One valve is a large coarse valve, the other is a smaller fine-tune valve. I'm trying to do PID control of a system. This isn't exactly LabVIEW, but hopefully someone has done this.

0 kommentar(er)

0 kommentar(er)